Walking on the street, large LED displays can be seen everywhere, some even tens of hundreds of square meters. People who do not know this will exclaim, “It’s amazing that today’s display screens can be made so large.”. In fact, there is nothing magical. The huge LED display screen we saw was actually spliced together by LED display manufacturers with small LED display boxes, seamlessly spliced.

Many people think that the full-color LED display screen is composed of a single screen, just like the LCD flat panel TV. In fact, the full-color LED display screen is composed of many unit board boxes. If a full-color LED display screen of several hundred square meters is a single structure, it is a big problem in transportation. Therefore, LED manufacturers take the box as the unit to facilitate transportation, installation and removal, maintenance, etc.

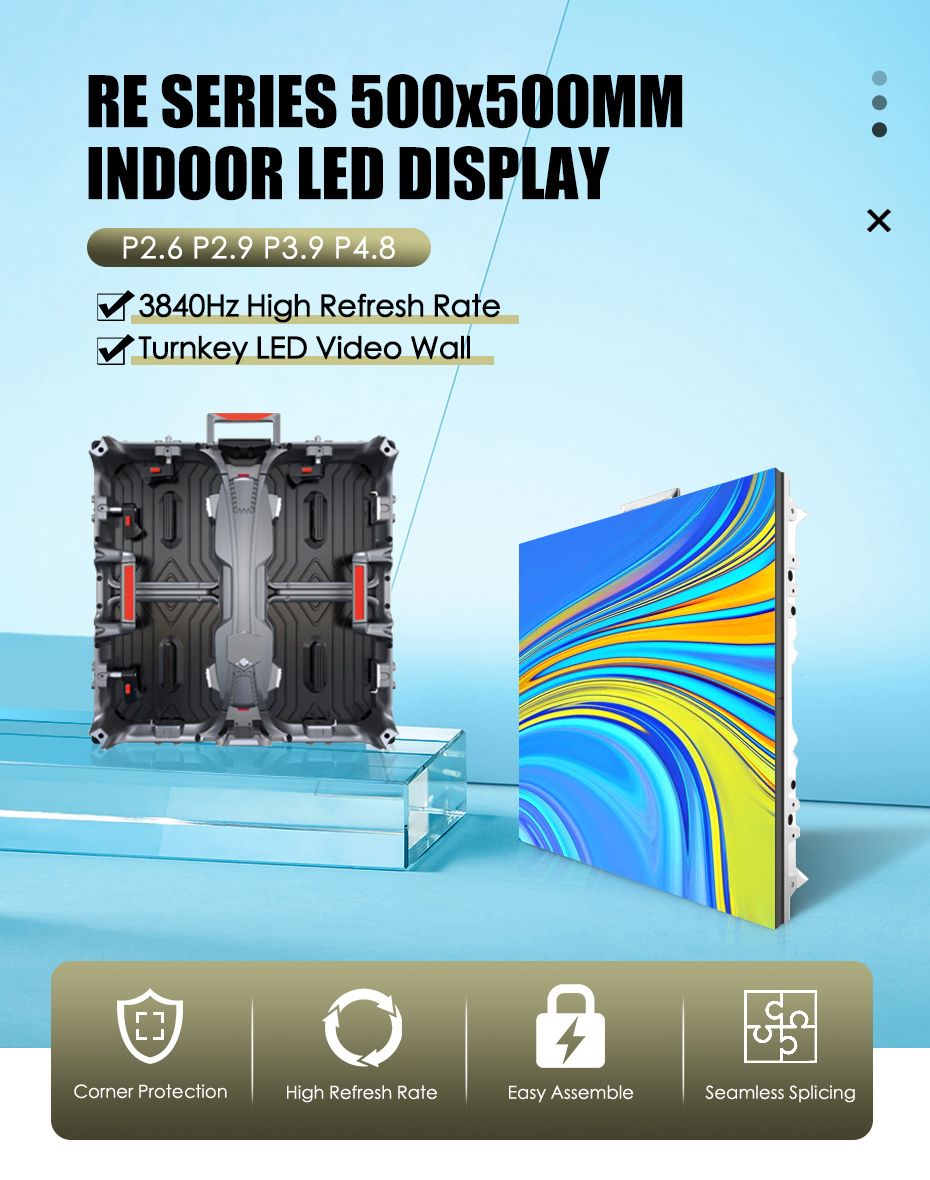

The die-casting aluminum box produced by the LED display manufacturer is light in weight, reasonable in structure and high in precision, and can realize seamless splicing. The * die-casting aluminum display screen produced by the LED display manufacturer is not only a simple upgrade of the traditional display box, but also a comprehensive optimization and update of the structure and performance. Die-casting aluminum led display screen is molded in a mold, which ensures the flatness of the box, effectively controls the tolerance range, and basically solves the problem of the seam of the box; Humanized design, more convenient and light installation, and more reliable connection of box seams and connecting lines; Light weight, hoisting structure, more convenient and firm installation; Imported power connector is adopted for safe and reliable connection; Concealed connection is adopted for signal and power connection between boxes, and no trace of connection line can be seen after installation.

Therefore, in the industry of LED display screen, as long as customers place orders, they can do as much as they want, and the clarity effect is quite good.